Turning a Fragile Pricing Engine into a Scalable System

NDA Protected60-Second Summary (TL;DR)

The outcome: Delivered a redesigned enterprise pricing system under a tight, non-negotiable deadline without increasing delivery or compliance risk. Reduced pricing confusion and errors by making complex logic transparent and explainable. Aligned design, research, product, and engineering around a single delivery plan.

Why it mattered: Leadership needed confidence that a fragile legacy pricing workflow could be replaced in weeks, not months. Engineering needed early clarity to avoid late-stage rework. The business needed a credible pricing story ready for high-visibility demos.

What I did:

- Led design while running parallel design and research with the lead researcher, aligning daily as questions and concepts evolved.

- Designed ahead of finalized research, shaping research questions in real time to meet deadlines.

- Partnered closely with product owners and developers to set weekly expectations and delivery options.

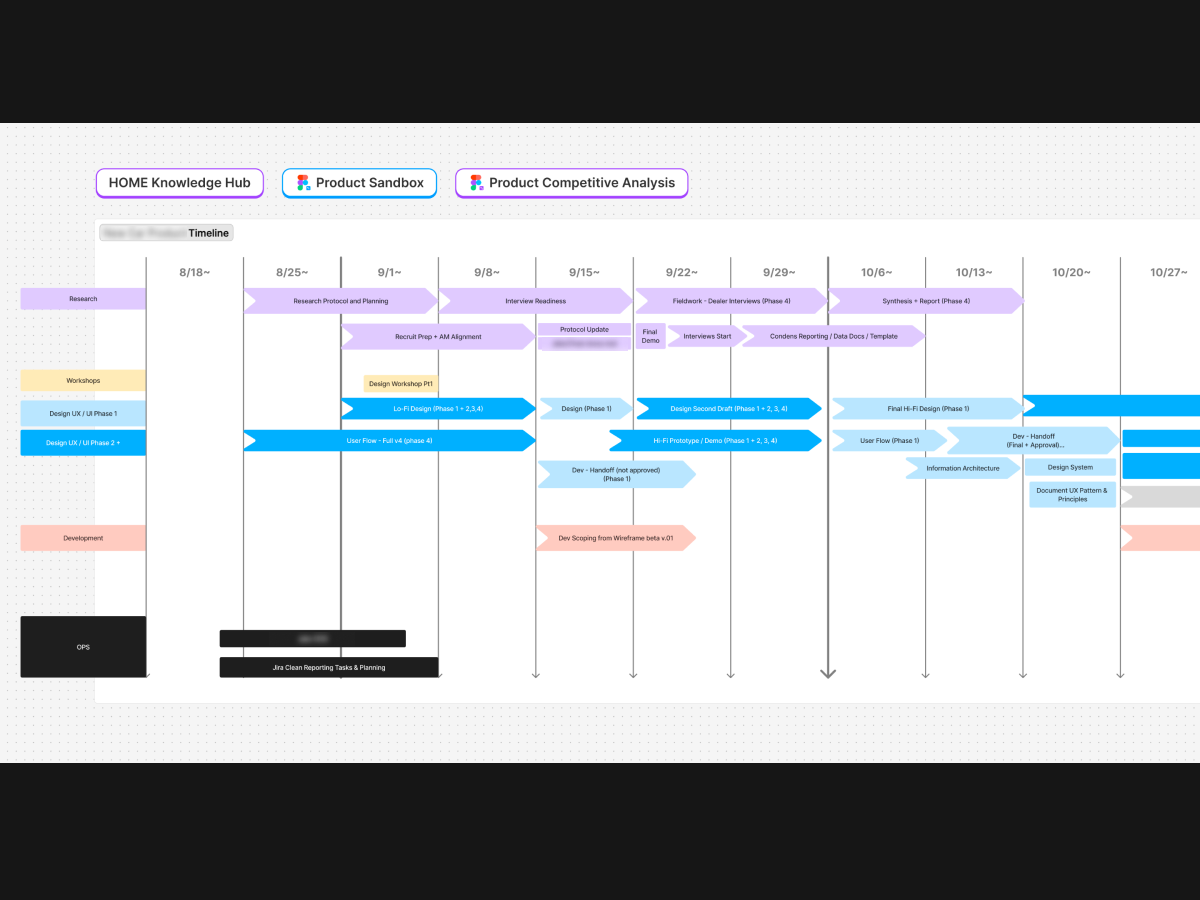

- Created a shared FigJam timeline to align leadership, product, research, design, and engineering.

Proof: Research validated core pricing concepts despite compressed timelines. Engineering began implementation earlier with fewer surprises. The timeline became the source of truth for scope and sequencing.

Timeframe: Late August – Mid October 2025, with continued design support during development due to build constraints.

External Link (After April 2026): NDA — not publicly available

Overview

Primary Impact:

Stabilized a fragile pricing workflow into a scalable, auditable system while meeting a deadline the organization had previously failed to hit.

Secondary Impacts:

- Reduced dealer pricing errors and compliance risk through transparent rebate logic.

- Enabled engineering to deliver predictably by surfacing scope, tradeoffs, and constraints early.

- Established a repeatable delivery model for complex, high-risk systems.

Role:

Lead Product Designer with end-to-end ownership of system design, UX architecture, and delivery alignment.

Scope:

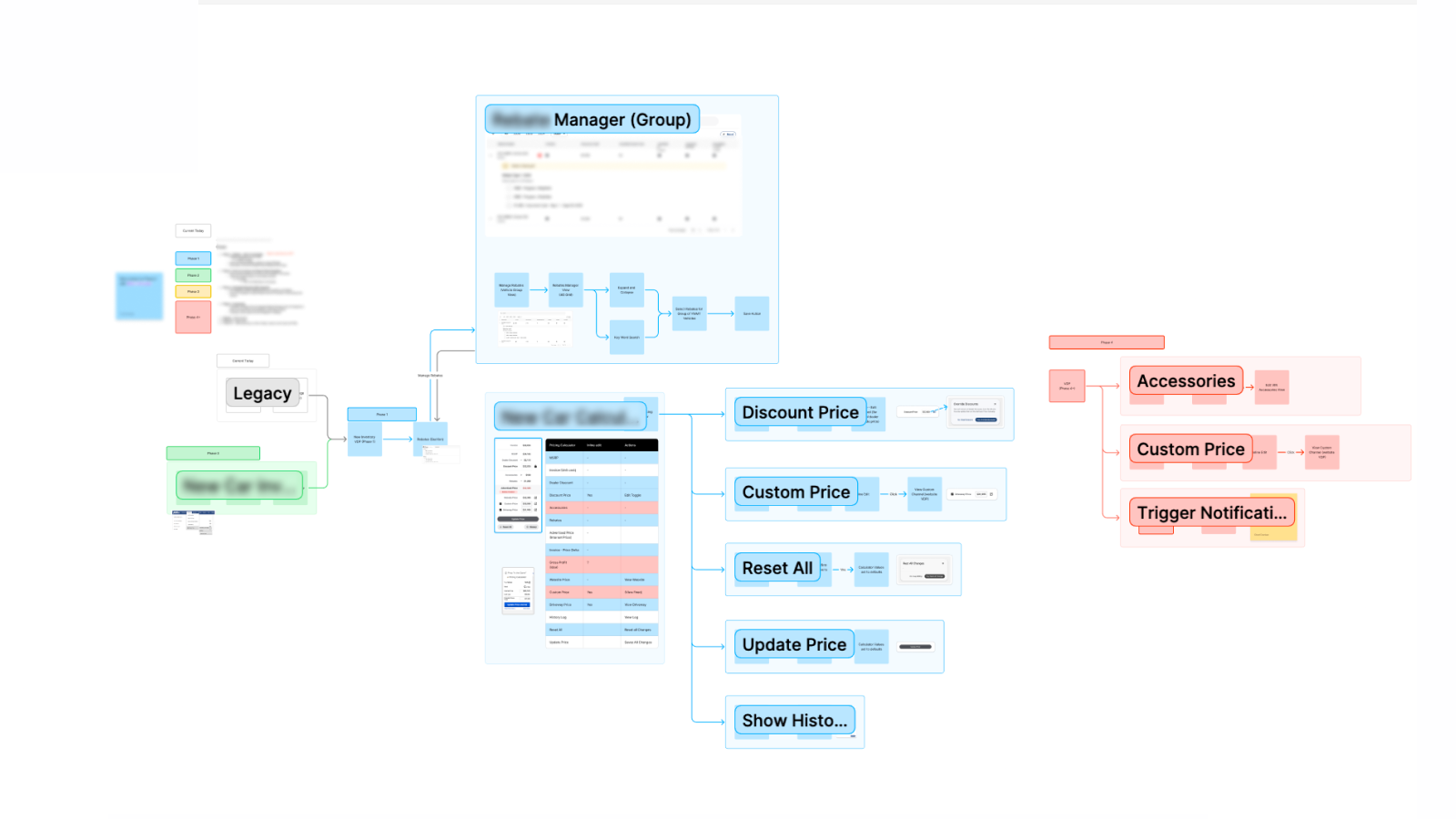

System-level redesign spanning pricing logic, rebate management, and a new VDP (Vehicle Display Page) foundation, across design, research, product, and engineering.

Why This Is Hard:

The work required redesigning a critical pricing system while requirements arrived late, scope shifted, legacy architecture resisted change, and the delivery timeline was fixed.

Why Leadership Needed Proof

- A non-movable external demo deadline created real delivery risk if the pricing system slipped or failed.

- The legacy pricing workflow was fragile and poorly understood, increasing the chance of compliance errors if changes were rushed.

- Engineering needed early clarity to scope complex logic, but design and research were still evolving.

- Leadership had seen previous pricing efforts stall due to late discovery and misaligned expectations.

What leadership needed answered:

- Can we replace a fragile pricing workflow in weeks without increasing risk?

- Can engineering start early without committing to the wrong solution?

- Is there a credible plan that aligns teams around scope, timing, and tradeoffs?

The Real Problem (Not the Obvious One)

What leadership thought the problem was:

- Dealers were struggling to apply rebates correctly.

- Pricing errors were creating compliance risk.

- The system needed a better rebate management UI.

What was missing from that framing:

- Rebate errors were a symptom, not the root cause.

- There was no centralized, controllable source of truth for rebates across store and vehicle levels.

- Incremental fixes had already made the legacy system fragile, risky to change, and understood by only a few people.

The real problem I identified:

- The organization lacked a scalable, transparent rebate system and a delivery approach that could handle its complexity.

- Scope volatility, unclear ownership, and fragmented documentation were compounding technical risk.

- Without intervention, the new system risked repeating the same fragility as the legacy one.

What would have broken if nothing changed:

- The project would miss its delivery window due to late discovery and shifting requirements.

- Engineering would be forced into reactive fixes, increasing long-term maintenance and compliance risk.

- Knowledge would concentrate in a few individuals, recreating the same bottlenecks that stalled past pricing efforts.

The actual need:

- A centralized, accurate, and auditable rebate system that dealers could control with confidence.

- A delivery model that surfaced unknowns early, absorbed scope change deliberately, and avoided incremental patchwork.

- Clear timelines, shared documentation, and explicit tradeoffs to prevent silent failure.

Operating Model We Proved

Strategy:

Run design and research in parallel to surface unknowns early, while using a shared timeline and explicit tradeoffs to keep delivery predictable under a fixed deadline.

Mental model:

- Design leads direction and scope framing early to unblock engineering.

- Research validates and refines in-flight decisions rather than waiting for a “ready” state.

- Product and engineering receive weekly options, not surprises.

- One shared plan replaces fragmented artifacts as the source of truth.

What this replaced:

- Sequential handoffs that delayed discovery until it was too late to course-correct.

- Unlinked documents and informal updates that hid scope changes.

- Late-stage validation that increased rework and delivery risk.

How it worked in practice:

- Produced a wireframe and scoping draft within two weeks to anchor feasibility and timeline discussions.

- Partnered daily with the lead researcher to shape research questions as designs evolved.

- Set weekly expectation checkpoints with product owners and developers, presenting clear delivery options and tradeoffs.

- Created a FigJam master timeline to align leadership, product, research, design, and engineering around scope, sequencing, and constraints.

What changed immediately when adopted:

- Engineering could start scoping and implementation earlier with clearer assumptions.

- Research validated the highest-risk decisions despite compressed timelines.

- Scope creep became visible and deliberate rather than implicit.

- Leadership gained confidence through a single, credible delivery plan.

The 3 Decisions That Drove the Outcome

Decision 1: Lock a Two-Week Scoping Draft Before Research Was Ready

Problem it solved:

Engineering needed clarity immediately to meet a non-movable deadline. Waiting for fully validated research would have blocked scoping and guaranteed a slip.

Options considered:

- Wait for research validation before sharing designs

- Share a rough, low-fidelity preview to unblock engineering

Tradeoff accepted:

Gave up the certainty of a fully research-validated blueprint in favor of speed and early alignment.

Decision:

Delivered a rough wireframe and scoping draft within two weeks as a preview handoff so engineering could begin API and logic planning in parallel.

Why this worked:

Early visibility surfaced unknowns while changes were still inexpensive.

Proof:

Developers reported reduced churn and fewer late-stage surprises, and final hi-fi designs were still delivered ahead of schedule.

Decision 2: Replace the Legacy Pricing Workflow Instead of Incremental Fixes

Problem it solved:

The existing pricing workflow was fragile, hard to reason about, and risky to extend. Incremental fixes had already created technical debt and institutional knowledge silos.

Options considered:

- Patch the legacy workflow to support new pricing logic

- Re-architect the pricing experience around a new, centralized system

Tradeoff accepted:

Temporarily lost feature parity with parts of the legacy workflow.

Decision:

Pivoted to a modern pricing architecture that could support transparent logic, live updates, and future expansion without compounding risk.

Why this worked:

A clean foundation reduced cognitive load for users and long-term technical debt for engineering.

Proof:

Dealers immediately reported improved clarity and trust in pricing decisions.

Decision 3: Use Phased Scope to Protect the MVP While Designing the Full System

Problem it solved:

The full pricing vision was too large to ship safely in one pass under the given timeline.

Options considered:

- Deliver the complete system in a single release

- Phase delivery while designing the full system upfront

Tradeoff accepted:

Delayed advanced features in favor of a stable and predictable MVP.

Decision:

Designed multiple future phases but strictly limited Phase 1 to the core pricing and rebate logic needed to succeed.

Why this worked:

Clear boundaries protected delivery while keeping the system future-proof.

Proof:

Engineering cited the phased structure as improving predictability and reducing confusion, and the model was reused on later projects.

Evidence and Validation

Delivery and execution signals:

- Engineering began scoping and implementation earlier than usual due to the two-week preview handoff.

- Design handoff landed ahead of schedule despite parallel research and shifting requirements.

- Fewer late-stage questions and rework compared to previous pricing initiatives.

Research and user validation:

- Core pricing and rebate concepts validated with dealers despite compressed timelines.

- Dealers consistently understood pricing logic, stacking rules, and control boundaries without additional explanation.

- Feedback confirmed increased trust driven by transparency rather than added features.

Behavioral and organizational signals:

- The FigJam timeline became the shared source of truth across design, research, product, engineering, and leadership.

- Scope changes were discussed explicitly and intentionally, rather than discovered during build.

- Engineering referenced the phased structure as improving predictability and reducing delivery risk.

What would not have happened otherwise:

- Engineering would have waited on finalized designs, compressing build time and increasing risk.

- Scope creep would have remained implicit, increasing the chance of missed deadlines.

- The new system would likely have repeated the same fragility and knowledge silos as the legacy workflow.

Constraints That Shaped the Work

Timeline pressure:

- The project operated under an extremely compressed timeline that no other design team in the organization had previously delivered against with similar scope and quality.

- Requirements were finalized late, leaving less than two months to scope, research, design, validate, and support development.

- A non-movable external demo deadline eliminated the option to slip or partially deliver.

Legacy system constraints:

- Initial work was constrained by the existing pricing and VDP (vehicle display page) architecture, which was fragile and difficult to extend safely.

- Midway through the project, it became clear that continuing within the legacy structure would recreate the same long-term risks.

- This forced a deliberate pivot to designing a new VDP foundation from the ground up.

Design system and architectural limits:

- The new VDP needed to leverage existing design system patterns to remain buildable within the timeline.

- Prior system patterns I had established enabled a faster pivot without sacrificing consistency or quality.

- New components had to be flexible enough to support future phases without expanding Phase 1 scope.

Phasing and scope constraints:

- Phase 1 required a tightly scoped MVP to ensure delivery, even though the full system vision extended across multiple future phases.

- Research and validation had to cover Phases 1 through 4 to avoid downstream rework and blind spots.

- Advanced features were intentionally designed and tested, but excluded from the initial release.

Organizational and resource constraints:

- Engineering capacity was limited and partially shared across teams.

- Design needed to absorb uncertainty and adjust sequencing to keep development unblocked.

- Clear tradeoffs and expectation-setting were required to prevent silent scope expansion.

Reflection (Forward-Looking)

Capability unlocked:

- Proved I can lead system-level design delivery under extreme constraint without sacrificing clarity or trust.

- Demonstrated that parallel design and research can be run safely when paired with explicit timelines, tradeoffs, and shared artifacts.

- Established a repeatable model for aligning design, research, product, and engineering around complex, high-risk systems.

How this changed my approach:

- I now treat operating models as a first-class design decision, not a background process.

- I prioritize early scoping artifacts to surface risk while changes are still inexpensive.

- I design full systems upfront, even when delivery must be phased, to avoid recreating legacy fragility.

- I am more explicit about tradeoffs and constraints to prevent silent failure.

What I look for next:

- Problems where system complexity, organizational pressure, and delivery risk intersect.

- Opportunities to replace brittle legacy workflows with scalable foundations.

- Work that requires aligning teams through clarity, not heroics.

- Challenges where design leadership directly influences execution quality and long-term system health.